Connect with Our Team for Trusted Aluminum Extrusion Support

In the demanding world of specialized manufacturing, complex projects require more than just materials; they demand technical collaboration, precise execution, and immediate communication. Whether the requirement involves fabricating unique aluminum profiles for a new product line or developing large scale illuminated display systems for an architectural installation, the process begins with establishing a clear and direct line of dialogue with the manufacturing specialist. Generic inquiries rarely yield the specific solutions required for highly customized components. Therefore, the initiation of the conversation is the first critical step toward transforming intricate designs into manufacturable reality.

The complexity inherent in custom metalworking and display technology means that every project possesses unique parameters from specific load bearing requirements and thermal management needs to exacting aesthetic and dimensional tolerances. Communicating these needs accurately upfront saves time, reduces the risk of expensive errors, and ensures that the proposed solution is perfectly tailored to the final application. A well structured, accessible channel for expert consultation is an invaluable resource for engineers and project managers operating under tight deadlines and strict quality controls.

The Gateway to Technical Collaboration

The process of sourcing specialized components requires a direct engagement with technical experts who understand the nuances of material science and fabrication feasibility. This initial outreach acts as the gateway to accessing comprehensive design analysis and production expertise. It is the moment where project constraints, functional requirements, and desired material characteristics are laid out for professional review. By prioritizing clear and open communication, the project minimizes ambiguity and accelerates the progression from concept to quote.

A reliable manufacturer ensures this initial consultation is straightforward, providing dedicated methods for submitting detailed technical specifications, CAD files, and project schedules. This streamlined process allows the engineering team to quickly assess the project's requirements, identify potential manufacturing efficiencies, and begin the critical process of design for manufacturability review, setting a strong, confident tone for the partnership ahead.

Explore more: https://www.classicmodul.com/contact

The First Step to Project Realization

For engineers and procurement teams ready to move their specialized designs forward, initiating a conversation with a dedicated fabrication expert is essential. Making this connection is the moment to share detailed specifications and project goals. Taking the initiative to engage directly allows designers to receive immediate feedback on the feasibility of their intricate concepts and the most cost effective paths to production. This direct connection ensures that the proposed solution precisely matches the unique demands of the project, whether it involves complex contact requirements for aluminum profiles or specialized lighting configurations for custom displays.

The initial dialogue provides the opportunity to discuss critical details that are often overlooked in standard inquiries. This includes specific metallurgical needs, such as the required temper and alloy grade for specialized structural loads, or the exact electrical and graphic specifications for custom illuminated enclosures. This focused consultation ensures that all variables are accounted for upfront, minimizing the potential for costly revisions later in the production cycle and establishing a foundation of shared technical understanding.

Addressing Complex Customization Needs

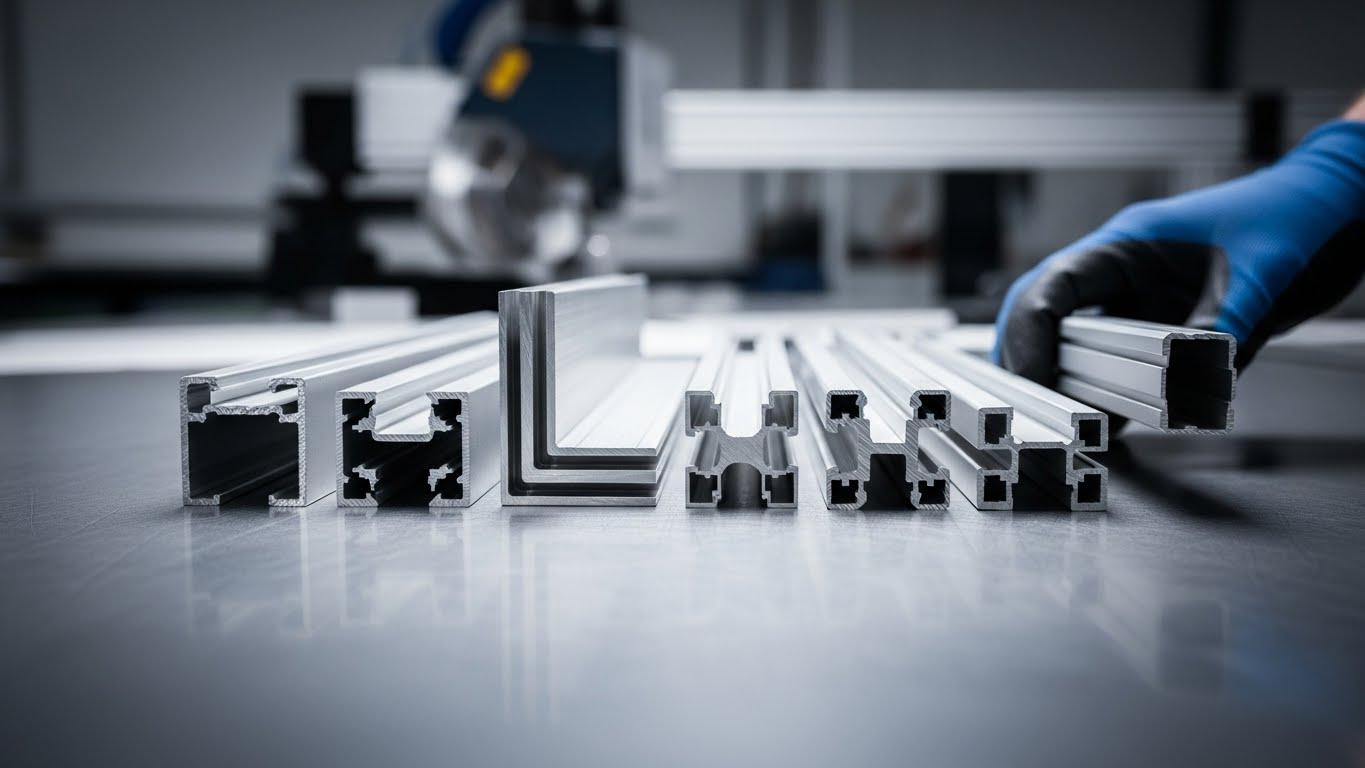

Custom fabrication demands a clear articulation of complex requirements. For aluminum profiles, this may involve discussing the creation of specialized hollow voids, asymmetric features, or internal channels necessary for integrated fastening or thermal management. For visual displays, the conversation centers on non standard dimensions, curved frames, integrated mounting solutions, and the required surface finish to match the architectural surroundings. Experts in these fields utilize this information to select the correct tooling, determine the necessary secondary machining processes, and calculate accurate lead times.

A trusted partner offers more than just a simple quotation; they provide actionable technical insights. This might include recommending slight modifications to a design that could significantly reduce material waste or recommending an alternative surface treatment that provides better long term durability for the intended operating environment. This consultative approach demonstrates a commitment to the client's overall project success, not just the sale of a component.

Streamlining the Sourcing Logistics

Beyond the technical specification, the initial engagement is crucial for establishing the logistics and quality assurance framework for the project. Discussions cover necessary production volumes, packaging requirements, and preferred shipping methods. For global or multi site projects, this planning phase is essential for ensuring components arrive precisely when and where they are needed, fully fabricated and ready for immediate assembly.

Furthermore, communication allows for the mutual definition of quality control benchmarks. This includes defining the acceptable dimensional tolerances for the final component and outlining the inspection process. Establishing these standards upfront ensures that all parties share a clear understanding of the expected product quality, providing confidence that the delivered components will integrate flawlessly into the final product or installation.

Conclusion: Building Projects on a Foundation of Dialogue

The successful execution of projects requiring high precision aluminum profiles and custom display systems hinges on a technical partnership built on clear and continuous dialogue. Taking the initiative to engage directly with specialized manufacturers provides immediate access to essential expertise, ensures design optimization, and simplifies the complex logistical demands of custom fabrication. This consultative approach accelerates the journey from concept design to final delivery, ensuring that specialized components are procured with confidence and integrated with absolute precision, driving overall project success.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness